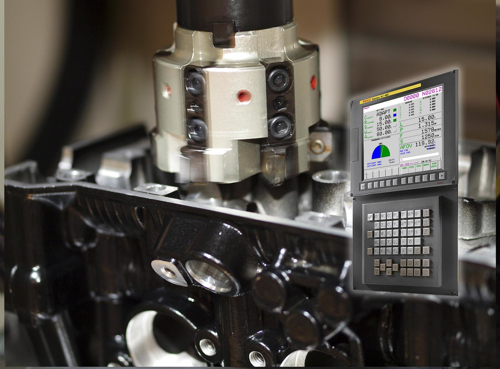

New Adaptive Control Solution Reduces Cycle Times Up to 40% and Improves Material Removal By Automatically Optimizing the Cutting Feedrate

FANUC Factory Automation America (FANUC FA America) has integrated their new iAdapt®s adaptive control solution into the CNC system for increased machine tool productivity. The iAdapt®S improves material removal and minimizes cycle time by automatically optimizing the cutting feedrate based on the actual spindle load. Additionally, integration of the iAdapt®S product within the CNC now eliminates the need for mounting space, simplifying installation while improving the capabilities of the original iAdapt® product.

The original iAdapt® product introduced the concept of roughing cycle productivity to CNC customers. The “On Demand” control feature simplified the use of the adaptive control by making it easy to setup and operate.

The new iAdapt®S has an arsenal of improvements which allows the operator to improve machine cycle time and tool life. By automatically optimizing the cutting feedrate based on the actual spindle load, iAdapt®S improves material removal and minimizes cycle time. In fact, productivity is increased as cycle times are reduced by up to 40% as every part is automatically optimized in real-time, including the first. iAdapt®S compensates for material and process variations including: material hardness, tool wear, depth of cut and width of cut. Additionally, feedrate control is 100 times finer which increases the responsiveness and accuracy of the adaptive control. To view and improve the machining process, a graphing feature has been added, which displays both the spindle load and feedrate override versus time. A new 64-entry setting table has been introduced in iAdapt®S which allows easy saving of settings for later use and recall. A new Torque Override feature has been added to allow the operator to dynamically modify the adaptive control set point during the machining cycle.

Additionally, iAdapt®S keeps roughing tools fully loaded, putting the heat into the chips rather than the part, thus extending tool life. As a result, there are fewer minor stoppages which further increases productivity and reduces labor costs.

Want more information? Click below.