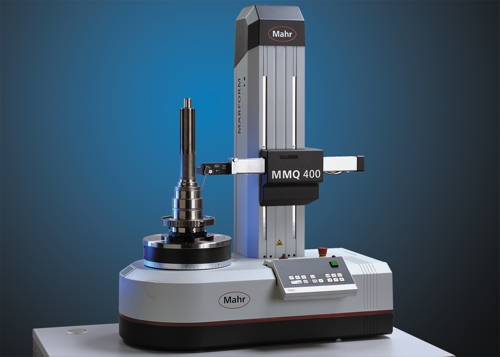

Redesigned Measurement System Dramatically Increases Speed and Resolution with Spacing as Tight as 0.005 Microns

The MarForm MMQ 400-2 measurement system integrates a new controller which allows the measurement of surface finish parameters according to ISO, ASME, and JIS standards. With dramatically increased speed and resolution, the MMQ400-2 samples data with spacing as tight as 0.005 microns. Benefits include reduced set-up and cycle times, and cost savings from using a single system for both form and surface measurements.

The MarForm MMQ 400-2 Formtester was a ground up redesign which delivers a machine that is more robust, less sensitive to environmental influences, faster, more flexible, and more accurate than comparable systems. The MMQ 400-2 offers an impressive array of features, including extremely solid construction with a generously dimensioned, reinforced steel base. High-precision mechanical bearings for the rotary table eliminate the need for an air supply, and all motors and electronic components have been thermally isolated to enhance stability. Wherever possible, homogeneous materials have been used in construction to minimize the effects of thermal expansion.

The skidded probe roughness package for the MMQ 400-2 utilizes the same diamond tipped PHT stylus as is used on Mahr Federal's popular PS1 and M300 surface finish machines, and the same MarWin-based surface finish software as the MarSurf® XR 20. The stylus is mounted opposite the ruby tipped form probe on the MMQ 400-2's motorized T7W probe head. The MMQ 400-2 automatically swivels the probe to apply the diamond stylus, and changes from horizontal to vertical measurement as needed, utilizing standard surface finish parameter cut-off lengths. A skidless probe measuring option is also available utilizing diamond tipped styli that are directly mounted to the T7W probe head.

Several versions of the MMQ 400-2 Formtester are available. Options include: manual or motorized center and tilt tables; vertical Z-axis length of 350 mm, 500 mm, or 900 mm for long shafts; and horizontal X-axis of 180 mm or 280 mm. All measuring axes are fully motorized. A selection of available probes—including the T7W 360 motorized bi-directional probe, and the manual T20W probe—further enhances measuring flexibility.

Mahr Federal will be featuring the new version of the MarForm MMQ 400-2, at Quality Expo 2011, September 20-22, 2011, at McCormick Place North, Chicago, IL.

Want more information? Click below.