One Plant's Switch to Corkscrew Milling Cut Cycle Time 3 to 1, Improved Tool Life 10 to 1, and Saved $40,000 a Year

The idea of plunging vertically into thick solid metal can require a leap of faith. But one shop owner saw a demo of the process on guidepin holes in wrought tool steel diesets and then bought the tool on the spot.

Large hole-making in ferrous metals can make for some pretty slow going. Big twist drills take a lot of power and can get expensive and hard to find in odd sizes. Flame cutting is cumbersome, leaves a lot for finishing, and works only on flat plate. Trepanning, with its expensive dedicated tools, is limited to repetitive high volume work. Orbital milling, while faster and more versatile, raises the risk of snapping off the brittle solid carbide endmills like toothpicks.

By switching to corkscrew milling, Baldor Electric is saving time and money on large-diameter holes, enterprise wide. Process has proved much more cost effective and secure than orbital milling. Indexable Ingersoll Hi-Feed Deka face mill opens the holes – from solid – in one third the time and eliminates tool breakage and regrinding. Insert edges outlast the solid carbide endmill by up to 10 to 1 – reliably.

Recently, Baldor Electric Company’s Gainesville, GA plant improved the large hole-making process on one part so successfully that they adapted it for ten other jobs at the same site and are considering it at several other plants. A member of the ABB Group, Baldor-Gainesville has 400 employees and runs 24/6 to produce AC and DC motors ranging from 1 to 1500 HP.

Big Holes Three Times Faster

By switching to corkscrew milling with an indexable Ingersoll Hi-Feed Deka face mill for holes over 1.500 inches, Baldor has cut cycle time by three to one on average and improved tool life by ten to one. Previously their standard process was orbital milling. The holes are then finished by boring, as before. The annualized saving from the process change at the Gainesville plant alone tops $40,000 a year.

It all began in early 2010 when Darimus Glasper, manufacturing engineering technician at Gainesville, started looking around for a faster way to open three-inch holes in a ductile iron casting with two-inch thick walls. The part is an explosion-proof cover, which encloses the electrical leads in large motors. Annual volume is 100 pieces, done intermittently in 10-piece lots.

Rugged Ingersoll Hi-Feed Deka facemill withstands the lateral and impact forces associated with corkscrew milling. It is twice the diameter of the previous solid carbide endmill, so it’s less subject to deflection and leaves no slug.

“Because of the workpiece geometry, the holes must be drilled from solid in a long-reach setup,” he said. “Not only was it slow going with the orbiting method and the solid carbide tool; we also went through a lot of tools.” Moreover operators were concerned because the spindle load meter read 90% even at that slow rate.

The Old Way—Slow Going

At the time, Baldor’s standard practice to rough out the holes was orbital milling with a ¾ inch four-flute solid carbide end mill. In orbital milling you plunge about 0.100 inch then orbit the tool at a very careful feedrate (so it doesn’t snap off as brittle solid carbide endmills are prone to do). Then you repeat the process until you break through, hoping that the resulting slug doesn’t pose a safety hazard or damage the tool. It’s basically start-and-stop. For each hole in the two- inch thick walls, it took about 20 steps.

Mr. Glasper chose the explosion proof cover for starters because, as one of the plant’s higher volume items requiring large holes, the company looks closely at it in sourcing because of price. “Solve it on the highest-volume part, and we get the biggest immediate payback,” he explained.

Looking for Ideas

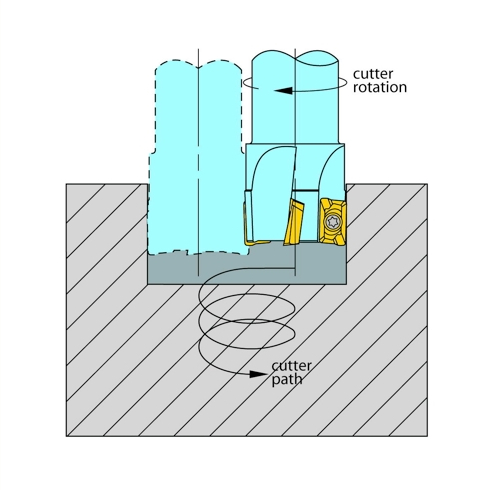

Note the 70 degree lead angle that creates smooth entry and reduces lateral forces as the tool orbits.

For ideas he asked Ingersoll’s Chris Pope, who suggested the corkscrew technique using a larger-diameter indexable mill with high feed inserts. “In corkscrew milling, the cutter advances continuously as it orbits,” Mr. Pope explained. “And the high-feed insert geometry means you can advance faster with shallower cuts, getting through the material faster while reducing cutting forces and spindle loads.”

Background

Corkscrew milling has been around for a number of years, but until recently was in limited use. In corkscrew milling, the toolpath is helical and continuous, not stepwise as in orbital milling. Principal applications included already-opened holes and thin materials, and horizontal setups where gravity took care of chip clearance.

The idea of plunging vertically into thick solid metal can require a leap of faith. In another Georgia plant, a small job shop, the owner saw a demo of the process on guidepin holes in wrought tool steel diesets. He bought the tool on the spot and jotted down the field engineer’s recommended parameters. Then he ran it in scrap wood for weeks and weeks before working up enough courage to run it on a real workpiece. Once he finally got running, holemaking time dropped by eight to one.

Here's the team that first made it happen at Baldor Electric - Gainesville. Left to right: Johnny Edenfield, Ingersoll field sales engineer; Chris Pope, Gamco Services sales engineer (distributor rep formerly with Ingersoll who helped initiate the change); David Rhodes, Ingersoll key account product manager; and Darimus Glasper, Baldor manufacturing engineer. The method change to corkscrew milling improves production of large holes in nine different parts, and the idea is starting to spread to enterprise-wide.

Eye-Opening Trial

In Chris Pope’s first trial run at Baldor, a three-flute Ingersoll Hi-Feed Dekamill running in the corkscrew mode completed each hole in five minutes, vs. 17 with the orbiting method. For the trial, the cutter helically advanced 0.031 inch per “orbit”, opening the hole in six revolutions, and orbited at 214 IPM vs 12. Surface speed was 800 SFPM, vs. 335.

The demo was so convincing that Mr. Glasper standardized on the corkscrew process within two weeks. “I’ve never seen a hole roughed out from solid that fast in my life,” said Mr. Glasper.

Re-engineering the process wasn’t a simple drop-in tool replacement. It involved reprogramming toolpaths and machine parameters as well as re-plumbing the machine to provide through-spindle flood coolant for chip clearance. Mr. Pope and Ingersoll southeast manager Phillip Johnson assisted with the parameter setting.

The change paid off immediately, however. Cycle time to rough out each hole in the cover dropped from 17 minutes to five, exactly as in the test, and edge life improved by 10 to 1. The previous solid carbide roughing cutter lasted through just one hole, while a set of edges on the indexable cutter lasts through ten. “The new method is not only much faster, it’s also much lower-maintenance,” says Mr. Glasper.

In about ten minutes, Baldor operator indexes inserts on Ingersoll Hi-Feed Deka indexable facemill that has tripled throughput of large holes. A set of edges outlasts previous solid carbide endmill by 10 to 1, and provides 10 edges per insert. Single 1.5 inch diameter facemill quickly roughs out all large hole sizes directly from solid, materially reducing tool inventory costs.

Here’s the math: Each insert has ten edges, yielding about 100 pieces apiece. A new set of three inserts, good for the next 100 pieces, costs much less than a single solid-carbide mill that goes dull after only one.

Completely Different Method, Tool

The production gains stem from a total method change based on completely different tool designs, according to Ingersoll’s milling product manager Mike Dieken. “First, the cut is continuous down the helical toolpath, not start-and-stop. Second, the indexable tool is twice the diameter as the solid carbide mill and has a steel cutter body,” he explains. “This makes it much better able to withstand the lateral forces involved inherent in the process at those high MRRs. Moreover, the 70 degree lead angle helps mitigate the impact and lateral forces at entry.”

He adds that the combination of high-feed insert geometry and fewer flutes enables much higher chip loads. “The 1.5 inch indexable Hi-Feed Deka facemill can withstand feed rates of 0.015- 0.040 inches per tooth vs. 0.002-0.006 for a ¾ inch solid carbide mill, Mr. Dieken continues. “And with fewer flutes, there is more room for the chips that come off so much faster.”

In corkscrew milling, cutter orbits into the work as it rotates, opening the hole much faster than drilling. Also, hole size depends on the toolpath program, not cutter size. This reduces drill inventory requirements since you don’t need a drill for each different hole diameter.

The change also removed a wild card, adds Chris Pope. “Since most holes at Gainesville measure less than three inches and the 1.5 inch tool covers more than half the diameter, there is no slug to upset things. All the metal exits as chips.” Since leading the process change, Mr. Pope joined Gamco Services, Inc. Baldor’s principal integrated supplier.

Spreading the Idea

Over the next several months as orders came in, Mr. Glasper applied the same process to other, smaller-volume workpieces. Today Baldor-Gainesville uses it on about nine different jobs with holes 1.500 inches and larger. Many involve odd diameters, for which standard twist drills are hard to find.

Soon after, Mr. Glasper and commodity manager Doug Bushey shared their experience via Baldor’s weekly idea-sharing conference calls among all plants. As a result, ten other Baldor plants are in various stages of implementing the corkscrew milling method.

“The process is tough to believe,” concludes Mr. Glasper, “but the results speak for themselves.”

Want more information? Click below.